In 2005 I started a new policy with my emergency service batteries. I no longer charge them before I take them on-site. Actually, I always take one battery charged the night-before, just in case. This is because I feel that if an emergency struck, I might not have the time to charge the batteries; I'd have to make do with what I had on hand.

This policy has been an interesting experiment and very informative. It has helped me weed out the poor batteries in my emergency battery supply. At that time I was very fortunate in having a good friend who can get used, but usually still good, batteries for our emergency service group.

Anyway, on Friday April 19th, 2002, I started selecting batteries to take to a walk-a-thon. I started with a little "kit" that is molded plastic and has a 7 AHr liquid-acid cell in it, two cigar sockets, voltmeter, on-off switches, etc. When I moved it, I noticed liquid on the table where it had been resting all winter. I quickly removed it to the garage and left it on some paper towels.

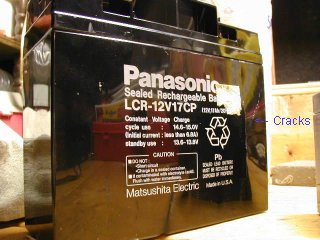

Next, I tested a 20 Ahr battery with my standard connector already attached. It read about 8 volts, not good for a 12V battery. Doing a quick visual inspection uncovered a bulge and a crack in the case. It was time to recycle that one, too.

(Image: CrackedBatt.jpg)

I disconnected the wires and plug from the defective battery and connected it to a battery that tested good. I'd never used this particular battery. It was one my friend Jim/K4CGY gave me out of a defective UPS system. This one tested good but he's required to replace all batteries when he changes one. The design of this battery was different than the last. The last one had a terminal on each of the two ends farthest away from each other, about eight inches, and pointing to the center towards each other. This new one had both terminals on one long side facing off the side. See the picture of the two batteries. Since I didn't pay attention to how I installed the bolts, Murphy was able to strike on Saturday.

(Image: SdangerBatt.jpg)

Saturday rolled around and I quickly loaded the last items in the car and drove to the site. Our EC wanted to test out our packet radio capabilities so I set up a packet station at Rest Stop 2. When I arrived on site and opened the trunk, I noticed that the two batteries I had placed on top of the case of extra parts, wires, connectors, and other things had both fallen off the case onto the trunk floor. I made a mental note that I didn't want these kinds of batteries on their side in my car trunk, so on the way home they would start out on the trunk floor.

I used the 14 AHr battery that had not been recharged. Cody, an eight-year-old boy we met at the park, was so interested in what we were doing and our "technology" that I let him "talk" on the packet radio a bit. I taught him how to measure voltage and he would come back every 10 to 15 minutes to talk with us, ask questions, and measure my batteries for me. I used the 14 AHr battery for the radio, an ICOM 2-AT, and the 24 AHr battery for the packet TNC and computer. Once connected, these batteries worked the three hours I needed, with hardly a dent in the voltage. I think the voltage change was less than 0.05 volts! I was very impressed and pleased that I had two such good batteries from the most recent batch Jim had supplied me with.

When I packed the batteries in the trunk this time, I did not put them on top of the case, I put them on the floor because I didn't want them to fall again. I placed them between the plastic case and my metal car tool kit. Normally when I do something like this, just to be safe, I place something between the battery and anything metallic and I usually cover the battery terminals. Of course, normally I don't allow any metallic bolt or metallic part to protrude beyond the battery case either. Three mistakes and my battery was toast.

I live in Carroll County in Maryland and I travel through farm country to get home. I was driving past a farm when I smelled something that reminded me of frying resistors or burning over-head lighting ballast resistors. I looked around. I still had about two miles to go, but I couldn't see anything burning in the area or any smoke columns.

When I arrived home I started to go in the house to get something to eat when I decided to unload the car first, starting with the stuff from the trunk. There, welded to the tool case, was what used to be that wonderful battery. It was still doing its best to supply everything it had to that darn tool case. It was hissing and steaming. It was bulging all over and the terminals were like wax, yet it still took me three or four good kicks to separate the two. I could not touch the battery because it was so hot and one terminal was now completely gone, melted like so much solder in a pool on the floor of the trunk. Needless to say, I got away from there and let what was left of the battery cool down. I did go eat then and hoped that it wouldn't explode. I didn't want to think of the damage that could cause.

(Image: BulgMelt.jpg)

After lunch, I came out and moved the battery to a cool spot in the garage. It was just cool enough to move with bare hands if I didn't hold it too long. I guess I still wasn't thinking. I should have used gloves and even put it into another container to be even safer before moving it. I was very lucky. A day later it was still in the garage and still had not leaked.

After I emptied the car, I realized it had a certain air about it . It smelled like it had been used to transport a thousand burning resistors. I left all the windows open, along with the trunk lid, in the hopes that in an hour or so I'd be able to drive to my next appointment in a car that smelled more like car and less like fried resistor. (An hour did not help much.)

Afterword: It took 24 hours of airing out the car to get rid of the smell,

My next task was to open the leaking battery case that I had had to leave behind and remove the bad battery & clean up the acid spill inside the case. That went without a hitch. I think that part of my normal thinking self was waking up. I was careful and slow, protecting both myself and my surroundings and I even thought far enough ahead (as I normally do) to supply my working area with a few plastic jugs of water already open and ready for emergency use. I did get some acid on my hand after I thought I'd cleaned everything up, so I did use a little of the water. Otherwise the removal went without a problem.

Murphy was not done with me yet. I had noticed that the people who put this battery case together had connected a red wire to a black wire. Since the unit had worked well for three years, I figured that was the way it was supposed to be. Thinking ahead, I did NOT disconnect the two wires because I knew that I would never remember or think that a black and red wire are supposed to be connected together unless I clearly marked them with those instructions ahead of time. Since I had nothing to mark them with, I went about disconnecting the case in another way.

Unfortunately, the device had a design flaw. I unsoldered the wires from the battery terminals and put the leaky battery in a safe place. The battery was leaking along a top seam. This was possible because the battery was installed on its side. This was not a well thought-out design and now I am sure I know why it was on sale for half price. A liquid-acid battery installed on its side? A red and black wire supposed to be connected together? What else did they do wrong? I would soon find out.

(Image: LeakyBatt.jpg)

I got another 7Ahr battery of the same form factor. I was not going to install it until I was sure it was good enough. I also wanted a gel-cell this time, which I didn't have. I simply wanted to test the recharge circuit since that was where I thought the problem was. It was designed to turn off when the battery reached full charge and I had noticed after leaving it to charge, about six months ago, that it was still charging the battery long after I thought it should have reached full charge. Apparently I was right, and that was probably when the seal had failed under the over-charge gas pressure. I connected my other 12 volt 7 AHr battery - white wire to positive, black wire to negative - and before I could get my charger hooked up, I heard hissing again and a pop. Smoke had come out of at least one component on the circuit board.

I don't think I have to tell you how ticked off I was then. I quickly disconnected the battery and traced the big black wire. Sure enough, it was connected to the positive terminal going to the outside of the case. I should have known. I should have marked it before I disconnected it from the original battery. Still I simply could not fathom anyone connecting a black wire to a positive battery terminal, so I simply didn't even consider that I should mark the battery leads.

In testing the circuit board I noticed that all connections still worked. Only one transisitor was fried and the charging circuit was definitely bad, but it was probably bad to begin with anyway. I may replace the transisitor when I get a gel-cell and I design a different recharge circuit, but that's for another day.

Lessons learned: Even a seasoned battery user can make mistakes when under stress, so double or triple check yourself Better yet, if possible, have another seasoned person check out your set-up. This is not really hard to do since we all like to show off our set-ups and designs. So, show it off and ask your friends for any possible problem areas they may see. The simple things we can all remember or perhaps put on a check list. I guess I need to write these things down as well since I forgot three of the most basic rules of battery safety: First, never allow any metallic object connected to your battery to protrude beyond the battery casing. If you'll notice, all car, UPS, boat, and golf-cart batteries are designed so that there is enough room going to the inside of the battery to allow for a long bolt. This is done on purpose because that's where the long side of the bolt should go. Second, place something non-conductive between the battery terminals and everything else around the battery. Third always protect the battery by covering it with a non-conductive material when transporting it. Batteries will move around in the trunk of your car, or in the engine compartment for that matter. Did you ever wonder why there are bars holding that thing down? Now you know why. I've noticed in some newer cars, the battery is in a plastic well with a top that bolts down. Just for safety, try to always keep at least one terminal covered. This will go a long way in keeping your battery safe even if you forget number one and/or two above.

(Image: sSafeBatt.jpg)

Finally, never assume that the people building that battery housing with those nifty connectors, switches, and voltmeters know what proper battery wire color coding is. ALWAYS observe and mark which wire goes where.

I hope none of you ever have to go through a Murphy weekend like mine and I hope that my experiences will help you to keep your emergency batteries and yourself safe.

Afterword: I decided to use my simple "Trickle Charger Plus" type of charging circuit for this system for now.

See the other emergency service articles accessable from the home page: http://cs.yrex.com/ke3fl

73 de KE3FL

Phil Karras

AEC Carroll County MD

ORS, OES, VE, & ARRL Life Member

updated: 05/18/2010